| Sign In | Join Free | My himfr.com |

|

| Sign In | Join Free | My himfr.com |

|

| Ask Lasest Price | |

| Brand Name : | WEEM |

| Model Number : | 1129 |

| Delivery Time : | 45 Workdays |

| Payment Terms : | T/T |

| Supply Ability : | 20000m /Day |

| Certification : | ISO 9001 & ISO 14001 |

WEEM 1129 Silicon Carbide Segmented Sanding Belt for Wide Panel Sanding on MDF / Plywood / Chipboard

Quick Detail:

WEEM 1129 segmented sanding belt is a premium solution engineered for wide belt sanding applications in the engineered wood industry. Constructed with Z-weight antistatic polyester cloth, premium silicon carbide grains, and resin-over-resin bonding, it delivers outstanding cutting power, dimensional stability, and extended belt life. Custom-made in sizes up to 3300 mm width, it is ideal for heavy-duty sanding lines on MDF, HDF, OSB, plywood, and chipboard panels.

| Backing: | Premium Z-Weight Waterproof Polyester Cloth |

| Treatment: | Antistatic |

| Coating: | Close Coated |

| Bonding: | Resin Over Resin |

| Grain: | Premium Silicon Carbide |

| Width: | 1828mm/72” ~ 3300mm/130” |

P24 | P36 | P40 | P50 | P60 | P80 | P100 | P120 | P150 | P180 | P220 | P240 | P280 | P320 | P400 |

○ | ○ | ● | ● | ● | ● | ● | ● | ● | ● | ○ | ○ | N/A | N/A | N/A |

● : Regular ○ : Custom

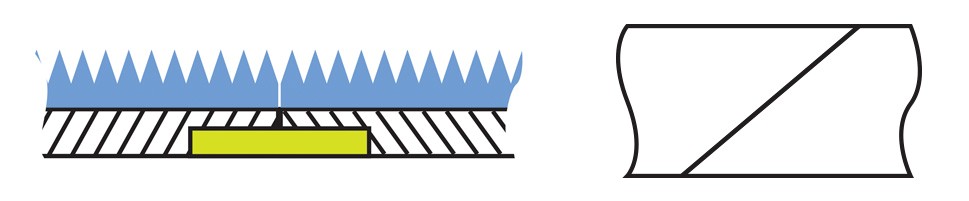

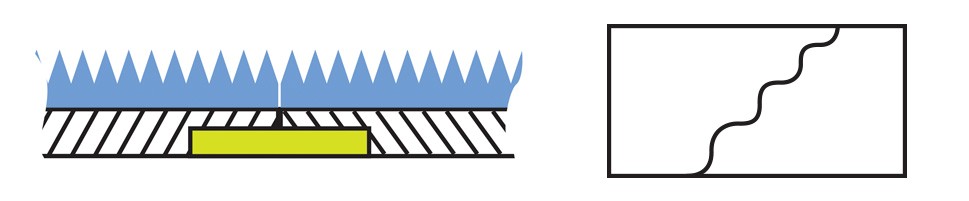

Joint Options:

WEEM 1129 wide belts are available with 4 types of joints to suit different sanding systems and requirements.

Tape on gain line joint:  as default.

as default.

Tape on gain zigzag joint:

Tape on butt line joint:

Tape on butt zigzag joint:

Designed for wide belt sanders such as Steinemann, Imeas, Sofuma, etc.

Woodworking / Wood-based Panel / MDF / HDF / OSB / Plywood / Laminate Sheet / Chipboard / Particle Board / Glass / Common Metal

Competitive Advantage:

Driven by over 20 years of expertise in the coated abrasives industry, WEEM 1129 segmented sanding belts are developed through rigorous research and benchmarking against global standards. Each component—from the abrasive grain to the resin system and backing substrate—is selected with one goal: maximum performance under industrial sanding conditions.

To address the mechanical challenges of very wide sanding belts, WEEM 1129 uses a custom-developed Z-weight antistatic polyester backing, offering excellent tensile strength, stiffness, and cross-directional stability. The result is a segmented belt that remains dimensionally stable across the entire sanding surface—even in high-speed, high-pressure operations.

The abrasive layer features high-purity silicon carbide grains, known for their sharpness and fine, linear scratch pattern, making them ideal for precision panel sanding. The closed-coat construction ensures maximum grain coverage, delivering fast stock removal, reduced loading, and extended belt life.

These belts are widely used on sanding systems from Steinemann, Imeas, Sofuma, and other wide-belt sander manufacturers.

To meet the unique mechanical demands of segmented belts—especially the need for cross-directional strength and dimensional stability—we partnered with fabric mills worldwide to develop an anti-static treated Z-weight polyester backing. This substrate offers high tensile strength, excellent stiffness, and stability across wide widths, making it ideal for sectional belt manufacturing.

Silicon carbide is a highly crystalline, sharp-cutting abrasive known for its ability to penetrate with minimal pressure. The high-purity grains selected for WEEM 1129 provide outstanding results when sanding engineered wood panels, non-ferrous metals such as brass and copper, as well as glass, rubber, plastics, and coatings. It is also well-suited for finishing operations on polyurethanes, primers, lacquers, and sealers.

The closed-coat structure ensures a dense distribution of abrasive grains, delivering fast stock removal, extended service life, and a consistently fine surface finish.

|

|